econfly

Member

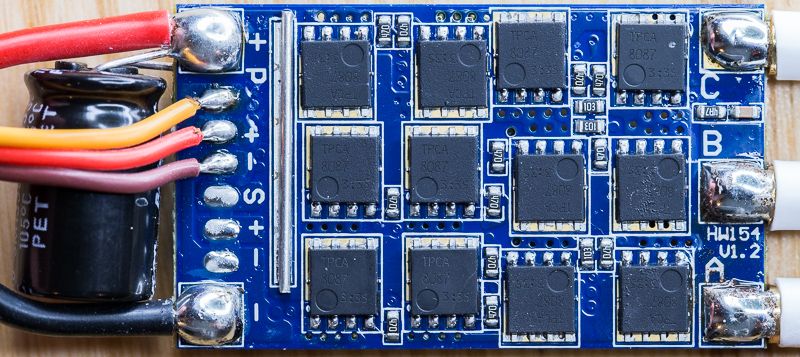

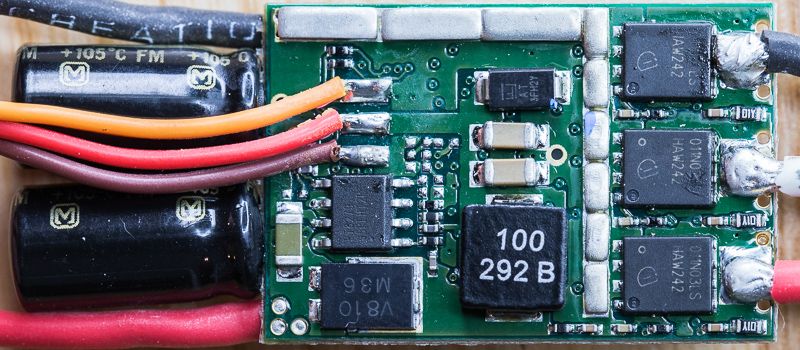

JETI HiCopter 30A Opto ESC Review

PART 1: OVERVIEW

In the simplest sense, what we want to know most about an ESC is whether it works. So let's deal with this most essential question first: Yes, these HiCopter ESCs work just fine. I plugged them into a test quad with a Naza v2 flight controller. In light wind everything worked as expected with stock gains and no issues whatsoever.

Feel free to skip the video. There is truly nothing unusual to see here.

https://vimeo.com/96621915

The ESCs are delivered in a nice box. The motor connections are the usual bullets, but with the handy flexibility of extension wires (as opposed to being soldered to the board). The power and signal wires are a comfortable length.

There are no settings for the HiCopter ESCs. There is no throttle calibration, no programming card, and no USB interface. Generally speaking, this is probably a good thing.

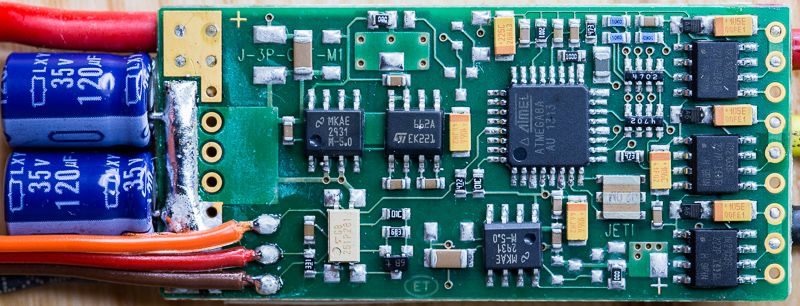

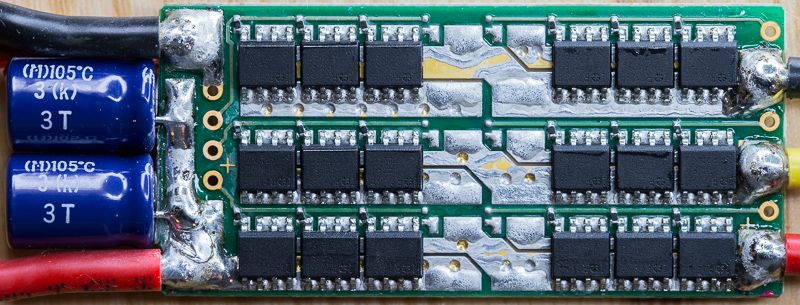

The 500Hz frequency response is nice, but typical (more on this later). More impressive is the optical separation of the signal side from the power delivery side of the ESC. ESCs tend to be marketed as “opto” when they do not output 5 volt power over the servo connection. But some “opto” ESCs produce their own 5 volt operating power from the main ESC power connection. This sounds reasonable until we realize that the connection can introduce noise back into the servo wires. You can’t just clip the voltage wire to fix the problem in many cases because the noise will be present on the ground wire too.

Thankfully, the HiCopters are true “opto” ESCs. They provide no power on the servo connection cable and require a 5v supply to operate. Most flight controllers will provide the needed power over the servo cable with no issues. This is a very nice feature, and is not to be assumed in just any “opto” ESC.

One almost ritualistic task — throttle setting — is noticeably absent. You shouldn’t care about this. Most flyers set ESC throttle endpoints incorrectly anyway, at least judging by what I see online. The basic problem is that people tend to set throttle with a direct connection to the radio receiver. Some even build special cables for this. In actual use, however, the flight controller is talking to the ESC, and will have its own independent throttle endpoints that need not match those of the radio. If your motors start when you want them to start, stop when you want them to stop, and deliver enough peak power to satisfy your flight demands then the throttle setting is just fine. The flip side of this is that you can’t really screw things up too badly by setting throttle endpoints incorrectly.

Many other ESC options are either anachronistic or confusing to the user. Sure, lipo destruction is bad, but worse is my copter falling out of the sky because the ESC is deciding to save the battery. It’s nice that the HiCopters have voltage cut-off preset to “the lowest possible level”. I would prefer no voltage cutoff at all. Admittedly, low-level cutoffs are often so low as to be effectively irrelevant, assuming the ESC correctly identifies the cell count of your lipos. The big worry is that the ESC misinterprets your lipo cell count and then cuts power inappropriately. In practice, I can’t get this to happen so I suppose it’s not worth worrying about. Nonetheless, it would be nice to see an ESC maker eliminate this feature altogether.

In sum, on specs and in actual use these are high-quality ESCs that perform well. But that’s no reason not to drill down on performance details. With modern multirotor flight controllers, the user only interacts with the ESC indirectly, and it is almost impossible for the typical flyer to separate the flight controller from the performance of the ESCs. This review attempts to get at a few direct measurements of ESC performance. Please comment on whether you find this helpful and if any additional metrics would be desirable.

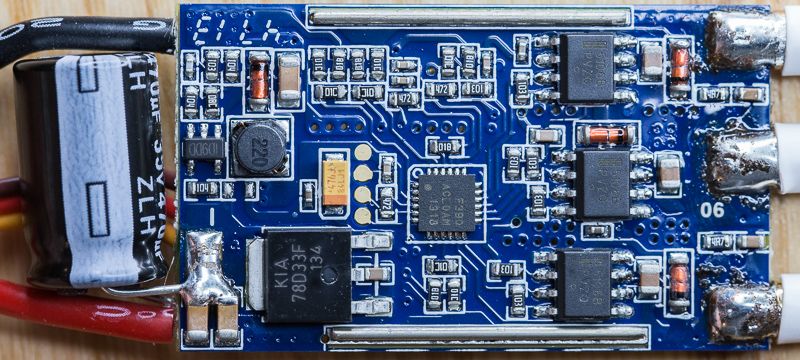

This review continues below with a section on how ESCs function (using the HiCopter ESC as example), followed by analysis of the HiCopter ESC as compared to a T-Motor 30A Pro Opto ESC and a Castle Creations Phoenix Talon 35A ESC.

PART 1: OVERVIEW

In the simplest sense, what we want to know most about an ESC is whether it works. So let's deal with this most essential question first: Yes, these HiCopter ESCs work just fine. I plugged them into a test quad with a Naza v2 flight controller. In light wind everything worked as expected with stock gains and no issues whatsoever.

Feel free to skip the video. There is truly nothing unusual to see here.

The ESCs are delivered in a nice box. The motor connections are the usual bullets, but with the handy flexibility of extension wires (as opposed to being soldered to the board). The power and signal wires are a comfortable length.

There are no settings for the HiCopter ESCs. There is no throttle calibration, no programming card, and no USB interface. Generally speaking, this is probably a good thing.

Each speed controller is pre-set from the factory with settings optimized for use with multi rotor aircraft stabilization systems. HiCOPTER controllers accept a control signal with a frequency of up to 500Hz. This allows them to accurately respond to any RPM change required by the control/stabilization unit of the multicopter. The motor control signal is galvanically (optically) separated from the flight battery in all HiCOPTER speed controllers. HiCOPTER speed controllers do not require or allow any programming changes. The propeller brakes are already switched off, the cut-off voltage is pre-set to the lowest possible level (depending on type) and the motor timing is set automatically by the speed controller. If you need to change the direction of rotation, simply swap any two of the motor wires.

The 500Hz frequency response is nice, but typical (more on this later). More impressive is the optical separation of the signal side from the power delivery side of the ESC. ESCs tend to be marketed as “opto” when they do not output 5 volt power over the servo connection. But some “opto” ESCs produce their own 5 volt operating power from the main ESC power connection. This sounds reasonable until we realize that the connection can introduce noise back into the servo wires. You can’t just clip the voltage wire to fix the problem in many cases because the noise will be present on the ground wire too.

Thankfully, the HiCopters are true “opto” ESCs. They provide no power on the servo connection cable and require a 5v supply to operate. Most flight controllers will provide the needed power over the servo cable with no issues. This is a very nice feature, and is not to be assumed in just any “opto” ESC.

One almost ritualistic task — throttle setting — is noticeably absent. You shouldn’t care about this. Most flyers set ESC throttle endpoints incorrectly anyway, at least judging by what I see online. The basic problem is that people tend to set throttle with a direct connection to the radio receiver. Some even build special cables for this. In actual use, however, the flight controller is talking to the ESC, and will have its own independent throttle endpoints that need not match those of the radio. If your motors start when you want them to start, stop when you want them to stop, and deliver enough peak power to satisfy your flight demands then the throttle setting is just fine. The flip side of this is that you can’t really screw things up too badly by setting throttle endpoints incorrectly.

Many other ESC options are either anachronistic or confusing to the user. Sure, lipo destruction is bad, but worse is my copter falling out of the sky because the ESC is deciding to save the battery. It’s nice that the HiCopters have voltage cut-off preset to “the lowest possible level”. I would prefer no voltage cutoff at all. Admittedly, low-level cutoffs are often so low as to be effectively irrelevant, assuming the ESC correctly identifies the cell count of your lipos. The big worry is that the ESC misinterprets your lipo cell count and then cuts power inappropriately. In practice, I can’t get this to happen so I suppose it’s not worth worrying about. Nonetheless, it would be nice to see an ESC maker eliminate this feature altogether.

In sum, on specs and in actual use these are high-quality ESCs that perform well. But that’s no reason not to drill down on performance details. With modern multirotor flight controllers, the user only interacts with the ESC indirectly, and it is almost impossible for the typical flyer to separate the flight controller from the performance of the ESCs. This review attempts to get at a few direct measurements of ESC performance. Please comment on whether you find this helpful and if any additional metrics would be desirable.

This review continues below with a section on how ESCs function (using the HiCopter ESC as example), followed by analysis of the HiCopter ESC as compared to a T-Motor 30A Pro Opto ESC and a Castle Creations Phoenix Talon 35A ESC.

Last edited by a moderator: